But with the OneFinity, you can drill your holes wherever you want.

Looks great, but does not conform to 32mm system. You can do lots of configurations and the space between fronts lines up with adjacent cabinets. You will also need some knobs (choose them on thingiverse) First test was OK (with a 6 mm drill. And the 3 mm space lines up with the adjacent cabinet. Inspired by (or copied from) official Festool LR32 system Settings of the rulers according to original, but with a 65 mm length (actually 65.1 mm but you probably will not be able to have a such precision) Base plate is made for Festool OF1010. Pot and pan roll outs, add 150 +3+150 303 mm high front. So now you have 5 drawer fronts, each 150 mm high. Now picture 5 drawer frontsneeding 3 mm space between each front. Subtract 5 mm for a little clearance between drawer front and countertop. The dado at the back is 16.5 mm wide x 2 mm deep. Spindle speed 24,000, feed rate 3000 mm / minute. With no clamps, the clearance height can be set to 2 mm, saving a lot of time.Įach gable takes about 5 minutes. Just made a special spoil board with holes placed in the right places so different size gable will still fit. You can forget about “system 32” as you can locate the holes wherever you want. The gable is the correct name for the cabinet side. I appreciate your willingness to share your expertise! What seemed like a great idea just a short time ago now appears to be a disaster in waiting.ĭoes anyone here have experience with this process? If you’ve been successful, how have you gone about the work? Bit selection? Straight plunge? Spiral? Peck? Feeds and speeds? RPM? If CNC really is a poor choice for this application that’s fine. Heat buildup, inadequate chip removal,having to spiral or peck the holes etc. Then there is a third option - CNC! I’ve read several articles that warn against drilling holes with a router.

#Festool lr32 system series#

It doesn’t take too many ruined cabinet panels to make the price of these two systems seem pretty reasonable. The hole series drilling system is a set for fast and simple production of series of holes for shelf supports, rear wall supports and fittings with the OF 1010 or OF 1400 router.

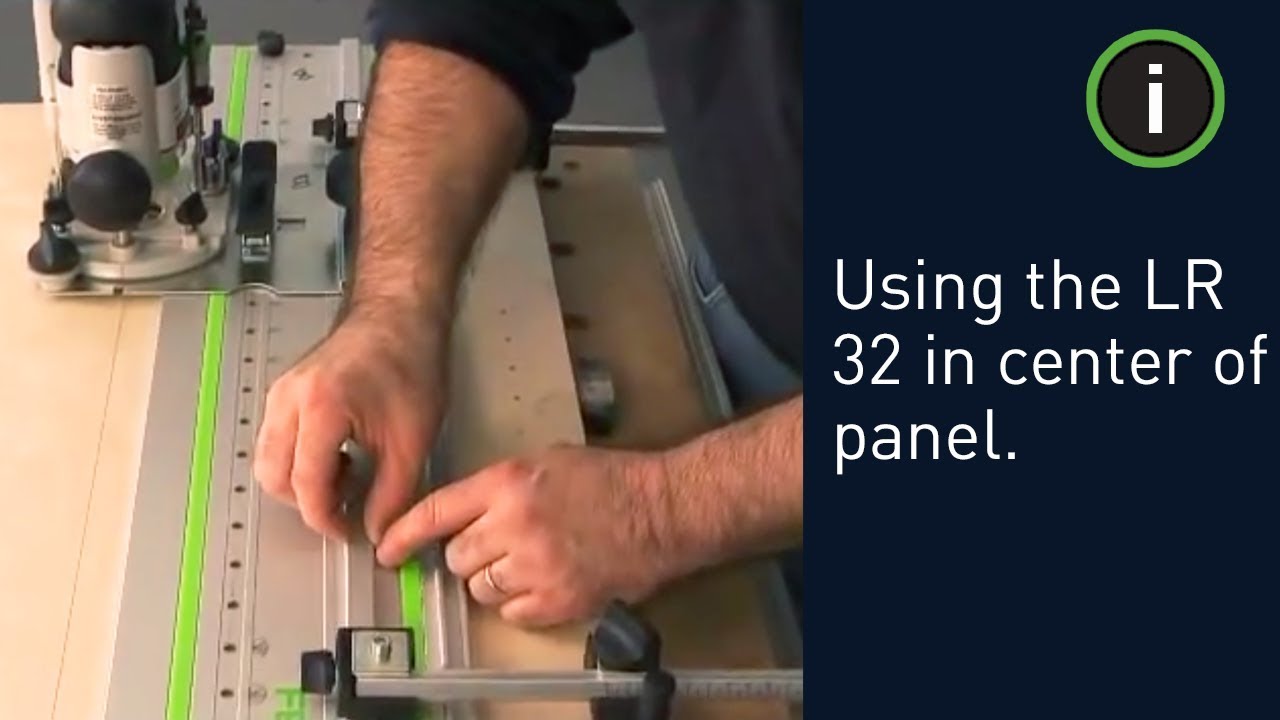

Adjust the guidance jaws on your circular saw to. Both are spendy, accurate, repeatable, and reliable. Create precise rows of holes spaced 32 mm apart with your guide rail, the LR 32 system and a Festool router. The two that are at the top of my list are the Festool LR32 system and the Schmitt32 system. Includes: Guide plate, Centering mandrel, 2 edge stops, 2 linear stops, 2 clamps, Operating wrench, 35 mm carbide-tipped European hinge boring bit, 2 carbide-tipped 5 mm shelf pin bits (one for through holes and one for stopped pin holes).I’ve spent considerable time researching System32 templates that are used with hand-held routers to drill shelf pin holes, assembly holes, and holes for System32 hardware. For use with the Festool OF 1010 and OF 1400 routers and guide rail system, the LR 32 System is supported by a 42in, 55in and a 95in rail (sold separately), to cover any size job.

#Festool lr32 system portable#

Invaluable for placing cup hinges (35mm) or setting shelf pin holes (based on 32mm spacing) in casework, this portable line boring system allows you do in the field what has traditionally been a shop-only job, possible only with large stationary equipment. With the LR 32 Hole Drilling System from Festool, you can precisely and efficiently build cabinets using the European frameless 32 mm system.

0 kommentar(er)

0 kommentar(er)